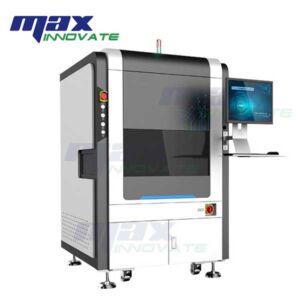

Product Details

1.CCD automatically recognizes mark point positioning and compensation to ensure high precision of cutting; 2.Exquisite visual system, improve the efficiency of programming. Convenience and stability; 3.Windows7 English and Chinese operating interface, simple programming, easy to learn and use; 4.Anti-static brush type upper dust suction device, dust collection rate increased by 90% and high cleanliness; 5.The rotating part is driven by servo and cut by imported high-speed spindle Our advantages: 1.We have a high tech team who can provide a series of professional technical support for our customers; 2.We are professional SMT&DIP machine factory in China for over 20 years; 3.Strict QC System. We will check two times with your orders. The first time is during mass production and the second time is prior to shipment. We will check each and test machine before shipment. 4.Competitive price. You can get a competitive price from here. Our price is factory price. Our purpose: customer oriented, quality first. 5.All machine size is customized,provide Non-standard service; We sincerely hope to work together with every client, to build the long-term business and friendship. Believe in us, Believe in professional!

Specifications

| ModelAC-610-C | Working rangeY550*X350 mm | Repeat accuracy±0.01mm |

| Cutting precision±0.05mm | Maximum travel strokeX:810 Y:370 Z:90mm | Spindle speedMAX.20000-60000rpm |

| Cutting speed0~100mm/s | Cutter sizeφ0.8-3.0mm | PowerAC220V 50/60HZ |

| Dimension1250(W)x1250(D)x1550(H)mm | Weight1000kg | Dust collector dimension860(W)*470(D)*730(H)mm |

| Dust collector voltageAC220V/380V 50/60HZ | Dust collector weight120KG | BrandMax Innovate |

Key Features

Key Features

Exquisite visual system

English and Chinese operating interface

Imported high-speed spindle

SMT&DIP machines factory in China! Good quality,Good serive, competitive price!